FARR Systems are the Solar Retrofitting Solution You’ve Been Looking For

By Western Colloid.

Fluid applied reinforced roof systems (FARR) are ideal for installations around solar panels and their mounting hardware.

Solar panels are more popular than ever nowadays due to technological improvements and because they are becoming increasingly cost-effective. Rising energy costs and green energy incentives are among the many reasons that building owners have added solar panels to their buildings. With more and more building owners looking into solar retrofitting on their facility, Western Colloid offers the perfect solution for dealing with a solar retrofit.

Out of sync

Modern solar panels are designed to last for decades. So is your building’s roof. Unfortunately, it’s extremely rare for the replacement of your roofing materials and your solar panels to coincide. This means, at some point, you will have to undertake the potentially challenging task of repairing or replacing your commercial roof without damaging your solar panels.

For many traditional roof systems, managing a retrofit with solar panels means removing the panels before undertaking the roof replacement. However, even in those cases where it’s necessary, solar panel removal is costly and inconvenient, because:

-

The solar panels are not generating electricity throughout the roof replacement. This will increase energy costs during the project.

-

Roofing contractors are often not qualified in removing or installing solar panels, meaning a second set of professionals is required. This will further increase costs and can delay project schedules until teams are available.

-

Any time solar panels are removed or installed, there is a risk of damage, both to the panels themselves as well as to the roof below. No one wants to add further costs to an already expensive roof retrofit by adding additional work to repair panels and roofing materials.

-

If solar panels are not properly reinstalled, they can damage the new roof, reducing its effective lifespan and, in some cases, even void the roof’s warranty.

The solar roof retrofitting solution you need

If your aging commercial roof needs a retrofit before a complete tear-off and replace is the only option — usually due to structural issues beneath — then you may have options available to you that would allow contractors to complete the retrofit without removing the solar panels.

A fluid applied reinforced roof (FARR) system is one that can be directly applied over the existing roofing material. FARR systems are applied in liquid form, either as a spray, by roller or soft brooms. This makes them ideally suited to work around solar panels and their mounting hardware.

Fluid applied roof coating systems typically consist of layers of either asphalt emulsion roof surfacing or acrylic coating, applied between layers of reinforced polyester fabric. The coating is applied first, followed by the fabric, with a final layer of coating applied afterward. This gives a seamless top layer, limiting the potential for cracks that could let water in.

A FARR system is a proven solution when dealing with a solar roof retrofit. Properly specified, it can be applied around the panels and mounting hardware without any kind of removal, and using a product like elastic cement can further reinforce the joints between the coating and hardware to improve overall waterproofness, especially around equipment like solar panels.

Coatings like asphalt emulsion and acrylic are also well suited to this kind of project because they are compatible with many different types of existing roofing materials, including BUR, modified bitumen, single ply, metal roofing, sprayed polyurethane foam and gravel roofs.

Choosing the right roof

If you’re selecting a FARR, you’ll need to choose between an asphalt emulsion surface coating or an all acrylic coating system, or a combination of both. Asphalt emulsion and acrylic coatings are both lightweight materials that won’t stress the structural capacity of your building. Both create a seamless waterproof coating that will last for decades.

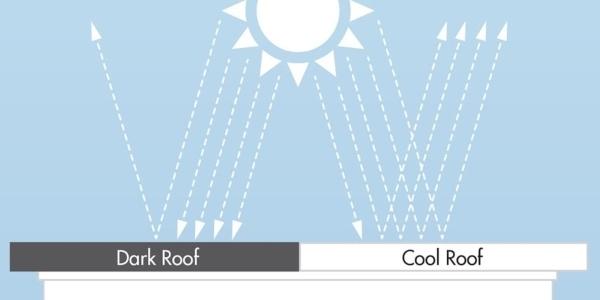

If energy efficiency is your priority — and if you’ve installed solar panels, energy efficiency is almost definitely a priority — then you may appreciate that these systems are finished with energy-efficient acrylic coatings. Acrylic coatings are generally white but can also be found in tans and greys that are light enough to qualify as energy efficient. This reduces the energy load on your building to keep it cool.

Tips for applying FARR systems

As with all roof work, make sure you get a detailed scope of work and cost estimate from your contractor before any work begins. When dealing with a solar roof retrofit, you particularly want to be clear on the measures they’ll take to protect the solar panels and hardware.

In cooler climates, contractors should apply FARR coatings before the temperatures dip for the winter. Asphalt emulsion and acrylic coatings should be applied at temperatures above 50 degrees and ideally on a day when there is no rain in the 48-hour forecast, in order to give the roof sufficient time to dry.

Once your contractors have completed the work, make sure they give you a detailed summary of the work completed, including any approved additions that weren’t in the original quote. Take pictures of the finished and cured coating so there are no disputes in the future about what work was done.

Have a question? AskARoofer.

Find your local roofing contractor in the RoofersCoffeeShop® Contractor Directory.

Original article source: Western Colloid

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In