History of Roofing - Hand Splitting Shakes

Hand-Splitting shakes with a mallet and a froe is one way to make shakes but I bet it would take a long time to make enough shakes to do a roof.

Today I was asked; I am replacing two rows of cedar shakes above a flat roof tie – in the roof, how many lineal feet does a bundle of shakes cover?

So, this is the subject of today's blog with a historical twist. Having installed tens of thousands of squares of cedar shakes in my life, you would think I would know this answer – but I had to think about it for a minute. I will bury the correct answer in the content of this blog, so you have to read it to find out the answer if you are interested. Do you know the answer? Who cares . . . . right? Believe it or not, there is a lot of roofers that visit the AskARoofer.com blogs and most roofers do not know the answer either. { 20 – 24 – 48 – 60 feet. } You get a one out of four chances to guess people.

The old way of splitting a bolt of cedar was using an iron blade called a froe. This blade was hand-forged with a handle on it. The froe was sharp on one side and was struck with a wooden mallet on the opposite side. The wood mallet should be used so as not to damage the metal froe by hitting it with a steel hammer. As the froe was placed on the logit, it was determined how thick the shake was to be and then struck by the large wooden mallet. Normally a few inches of the blade would protrude out of the side of the log so as to be continually hit downward and splitting the log into a shake. The handle was used to guide the froe to pry a create a taper but this takes much experience and skill.

The old way of splitting a bolt of cedar was using an iron blade called a froe. This blade was hand-forged with a handle on it. The froe was sharp on one side and was struck with a wooden mallet on the opposite side. The wood mallet should be used so as not to damage the metal froe by hitting it with a steel hammer. As the froe was placed on the logit, it was determined how thick the shake was to be and then struck by the large wooden mallet. Normally a few inches of the blade would protrude out of the side of the log so as to be continually hit downward and splitting the log into a shake. The handle was used to guide the froe to pry a create a taper but this takes much experience and skill.

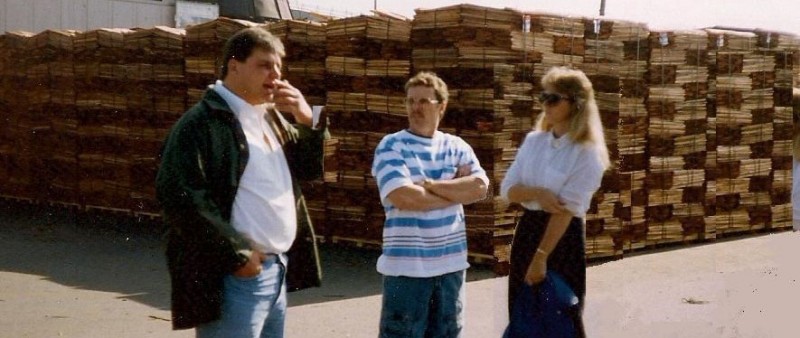

I was in Mission BC visiting this shake mill with my friend Dwight Douglas and my wife Judie in 1990. My buddy Stoney from Pacific Supply arranged a tour of one of the Meeker Mill in Mission BC. It was very interesting to see how a large shake mill worked from start to finish. We saw cedar logs plunked from its journey down the Fraser River, sawn into twenty-four-inch lengths, split, bundled into a beautiful cedar shakes for roofing. This mill was fully operational with large chains saws cutting the logs in the river. Once debarked they were sent up a steel conveyor to split the bolts into manageable sizes, then to the pneumatic splitter taking the place of the froe. A sawyer would saw the shake long ways one corner to opposite corner creating two shakes sawn on the back and split on the front side. Another sawyer then would edge trim and grade the shake, while the next phase was bundling them. A bundle of shakes when laid out in one continuous course covers twenty-four feet and takes five bundles to make one square laid at ten-inch exposure.

I was in Mission BC visiting this shake mill with my friend Dwight Douglas and my wife Judie in 1990. My buddy Stoney from Pacific Supply arranged a tour of one of the Meeker Mill in Mission BC. It was very interesting to see how a large shake mill worked from start to finish. We saw cedar logs plunked from its journey down the Fraser River, sawn into twenty-four-inch lengths, split, bundled into a beautiful cedar shakes for roofing. This mill was fully operational with large chains saws cutting the logs in the river. Once debarked they were sent up a steel conveyor to split the bolts into manageable sizes, then to the pneumatic splitter taking the place of the froe. A sawyer would saw the shake long ways one corner to opposite corner creating two shakes sawn on the back and split on the front side. Another sawyer then would edge trim and grade the shake, while the next phase was bundling them. A bundle of shakes when laid out in one continuous course covers twenty-four feet and takes five bundles to make one square laid at ten-inch exposure.

Our tour guide was Scott Meeker ( left ) back then who ran this company called Meeker Cedar Product LTD. The Meeker family has a long history in the cedar roofing products dating back to 1930. Townsend Meeker or who was known as Toke Meeker and brother Lincoln started a shingle mill in Mission British Columbia. After WWII Toke developed the sold the shake as an option for roofing your home and history shows many of the mills popped up to fill the demand in the USA. Since then, the Meeker family has to lead the industry in the production of cedar shingles and shakes with mills named Anbrooke, Clayton and Meeker Cedar Products LTD just to name a few. Many of us roofers have used their products for decades and still continue to do so as long as they produce cedar products.

So did you see the answer to the question? If not at least you know a little about the history of roofing and hand splitting cedar shakes.

Have a question? AskARoofer HERE

Need a contractor? Check out our list of Roofing Contractors HERE.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In