The History of Gravel Roof Restorations

By Western Colloid.

Learn more about the history of gravel roofs and how we go about restoring them using asphalt emulsion.

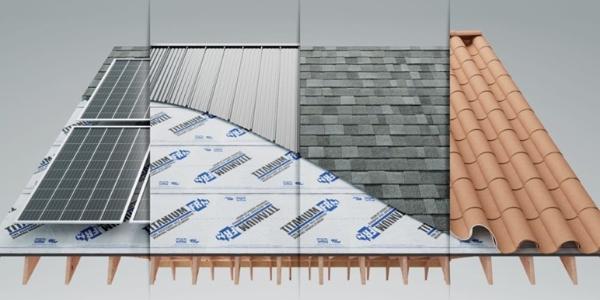

One of the earliest forms of roofing was built-up roofing which started in the early 1900s. This type of roofing was made of melted asphalt that was then reinforced with layers of felt. Over time, this felt material was replaced with fiberglass, but the same building principles were used with each roof containing two to four layers. Even then, roofers needed to add a surface over the roof layers.

Early applicators had two problems with surfacing a roof. One was UV degradation, especially in certain parts of the country. Roofers would coat the rooftops with hot asphalt and apply it every two or three years. They would put another coat of asphalt on it, leave it black and let it weather. But that brought up other issues, like big fires.

This led various governments to establish fire ratings for roofing materials. They decided that we needed roofs that weren't going to burn, and ideally even help against fire, as certain forms of asphalt can burn readily.

The solution was simple. There is one thing available that is almost universal around the country: gravel and rock. Whether you are in Maine, Florida, Ohio, Oklahoma, California or Washington, you can get gravel.

Gravel does three things:

- Gravel, or rock, adds a little bit of weight to the roof for wind resistance.

- It adds UV resistance because the sun can’t penetrate it. It doesn't keep the temperature cool, but the UVs are not going to degrade the asphalt.

- It is fire resistant. If you put enough gravel on a roof, you can get a fire rating with a paper towel! It is a terrific barrier to the heat.

With all the gravel roofs nationwide, the challenge of re-roofing arose. Instead of the expensive remove and replace option, we needed to come up with a way to restore the gravel roof.

Rock and gravel have a very rough surface texture because a good portion of the gravel has to be embedded in the asphalt. Applicators put on that layer of asphalt, then a layer of gravel is uniformly embedded into the asphalt and doesn't come off very easily. And you do want that layer to be on there.

Gravel roof restorations started to gain traction about 40 years ago. Companies like Tremco, leaders in the coating industry and Garland Company had products that they used on gravel roofs. Those were originally solvent based. Essentially what the early adopters did was go over that gravel roof that was all dried out and cracking and put this solvent-based asphalt product on it that would lay on there in a very thick layer. The solvents would then migrate down into the old asphalt and soften it up.

They had a lot of success for some years, but the number of solvents that were used with time made that not very desirable as they dried out and they tended to crack again.

Enter asphalt emulsion coatings. For over 40 years Western Colloid has been successfully restoring gravel roofs, and that's because of asphalt emulsion, which is an asphalt that isn't readily flammable. It is relatively inexpensive, so higher quantities are not cost prohibitive.

Asphalt emulsion is a combination of a straight run distilled asphalt. When it is mechanically ground with a bentonite clay and water it becomes a colloidal product, (hence the “Colloid” in our name). Once the water evaporates, it becomes a combination of bentonite clay and asphalt. And that results in two things: it's very waterproof and it's a low-cost product. Also, it has none of the traditional asphalt fumes.

Emulsion is sometimes challenging as far as estimating the amount needed. We have specifications, but even our specifications vary depending on the different gravel sizes used in different parts of the country.

As a rule, most of our gravel roof specifications end up using between a minimum of 18 gallons to 30 gallons of emulsion per 100 square feet. Contractors ask, “How much weight am I putting up there?” Think of it this way, you just took off 200 pounds of loose gravel and you are going to put back on 40 pounds of emulsion. You will not be even close to what you took off when you cleaned off the gravel.

Another thing to keep in mind is in estimating asphalt emulsion on a roof is that it is between 40-45% solids. It's not a high solids product, which means 55% of it evaporates away as water. When you spray on three eighths of an inch thick, it will dry to one eighth of an inch thick.

But for one thing, we never do a light spec on gravel where we might do a one ply of polyester reinforcement over a good cap sheet roof. We would never do one reinforcement over a gravel roof. This isn't a band aid roof. This is a substantial reinforced coating system that you're putting on there.

It does take some training and we've even helped other manufacturers. This is because after we put an asphalt emulsion flood coat on a gravel roof, we let that dry out well and then come back with at least two plies of polyester fabric in asphalt emulsion and possibly one ply in acrylic.

For the topcoats on these gravel projects, we chose acrylics 50 years ago and they still work today. We like water based because we find that they work well, especially if they're reinforced on a gravel roof.

A great example of this solution is a very large, well-known building in Texas some years ago. This roofing job was done with a combination of a flood coated gravel roof that was a chopped glass and emulsion with additional plies of polyester and emulsion, finished with polyester and acrylic on top. This high-profile building saved close to a million dollars as it had heavy insulation on it along with the gravel roof. If they had to tear off the entire roof with the insulation and re-install another product, it would have been a very costly roof.

On a side note, that building in Dallas withstood a huge hailstorm that came through with five-inch hail. Our gravel roof specifications have FM ratings, both with chopped fiberglass reinforcement and polyester reinforcement over gravel and have tested successful against hail.

If you have a gravel roof restoration project coming up, Western Colloid offers a terrific alternative to tearing that roof off. In addition to the savings mentioned above we can provide a renewable, sustainable, highly reflective roof system for the building, which will bring down energy, heating and cooling costs.

Contact Western Colloid today for more information.

Have a question? AskARoofer.

Find your local roofing contractor in the RoofersCoffeeShop® Contractor Directory.

About Western Colloid

For over 45 years Western Colloid has been recognized in the roofing industry as a leader in FARR – Fluid Applied Reinforced Roofing, Reflective Coating Systems and Premium Asphalt Sealcoats. Headquartered in Southern California, with five other manufacturing plants and distribution centers, Western Colloid is also known for extensive experience in coatings, pioneers in energy saving and cool roof products and unique paving solutions. For more information please visit us at www.westerncolloid.com.

Recommended For You

Meet Tremco’s AlphaGuard™ BIO roof restoration system

Read More ...

New Titanium® FR Self-adhered Underlayment Meets Wildland Urban Interface Fire Codes

Read More ...

Westlake Royal Roofing Solutions Showcasing Resilient, Energy Efficient Roofing Product Lines at 2023 International Roofing Expo

Read More ...

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In