Why Synthetic Felt Underlayments Are the Future

By Cass Jacoby.

Synthetic underlayments are taking over the roofing industry, which comes as no surprise given all the benefits.

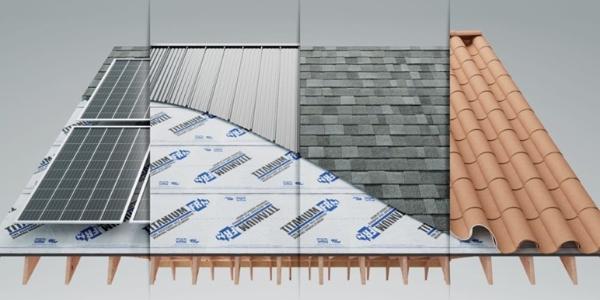

Often, when people think of roofs the first things that come to mind are shingles or metal roofing; rarely do people give a lot of thought to the underlayment. However, the underlayment is an integral part of a complete roofing system. This layer of protection applied directly onto the roof deck performs a critical role in protecting homes from moisture damage.

There are two main types of roofing underlayment: felt and synthetic. While every product has its pitfalls and benefits, many factors influence what is considered the right underlayment for a roof. Read on to learn about why more and more contractors and homeowners choose synthetic nearly every time.

Felt

Felt has long been the historic go-to of underlayments, as it is of the oldest type of roofing underlayment material. These underlayments are created by saturating paper or fiberglass mat with asphalt. The chief benefit is that this material is a budget-conscious choice for homeowners, as it is more economical in comparison to the synthetic underlayment.

“Asphalt-saturated felts have been and are still commonplace in steep-slope roofing systems because they are low-cost, readily available materials with which most people are familiar,” according to the Roofing Industry Educational Institute and the National Roofing Contractors Association. “Since these products have been around for so long, and people have become accustomed to their ease of installation and workability, they remain relatively steadfast in the marketplace.”

However, felt underlayments generally can’t be left exposed for more than a few hours, as the material may dry out or leach oils in the heat, which in turn, impacts the felt’s ability to protect against moisture. These kinds of underlayments are also prone to tearing in high winds and during the strain of installation. They also tend to weigh more and have slippery surfaces, making their installation difficult.

Synthetic

It was right around the turn of the century when manufacturers started developing and marketing synthetic underlayments. These new underlayments feature multi-layer designs that are the answer to the problems posed by traditional roofing felt.

Herein lies the reasoning as to why synthetic underlayments are so popular, unlike felt products that tend to absorb water, synthetic underlayments are usually made from long-lasting polymers, which provide added strength and longevity in addition to enhanced water-resistance. Synthetic material can last anywhere from 25 to 40 years, which nearly doubles the lifespan of a felt underlayment.

Additionally, since these underlayments are water repellant, they do not support mold growth, they lay flatter and can be exposed to the elements without the need for tarps or immediate dry in.

Synthetic underlayments have an extremely high tear strength compared to felt and are incredibly tough. The durability of synthetic underlayment makes it perfect for use on a roof that is not going to be installed immediately as the material will not be harmed from exposure to weather conditions. The material is suitable for extended UV and moisture exposure and can better withstand boot traffic.

This is important for homeowners and contractors concerned about moisture infiltration, especially if they plan to leave the underlayment exposed for a prolonged period of time. Further, synthetic underlayments tend to be lighter and faster to install as there is more material per role, making them a preferred choice for contractors and homeowners who want efficient installations.

The only drawback of synthetic underlayments is the higher upfront cost. However, it is worth noting that the investment in higher quality roofing materials can save money later, as this superior product can prevent costly issues in the future. A roof is more prone to leaks once its protective underlayment starts to break down, thus picking the underlayment with the greatest longevity is important in regard to minimizing future maintenance and maximizing the lifespan of a roof.

Conclusion

As you can see, synthetic roofing underlayment is the answer to the challenges posed by traditional roofing felt — and it represents a long-overdue advancement in roofing technology. When your customers want the toughest protection, offer them PALISADE™ synthetic roofing underlayment. The advanced technology of this product is specifically designed for steep-slope roofing applications no matter what the challenges are.

This premium quality, four-layer synthetic underlayment can take on the toughest conditions. It features their STRONGHOLD Skid Resistant Technology® for advanced protection, traction and safety. Plus, the underlayment is 100% felt free, made in the USA from synthetic lightweight, high strength polymer. Unlike felt paper, this synthetic polymer is unaffected by water absorption, which means it does not support mold growth, lays flatter and you can leave the roof uncovered without the need for tarps or immediate dry in.

Have a question? AskARoofer.

Find your local roofing contractor in the RoofersCoffeeShop® Contractor Directory.

About Cass

Cass works as a reporter/writer for RoofersCoffeeShop, MetalCoffeeShop AskARoofer and MetalCoffeeShop. When she isn’t writing about roofs, she is putting her Master degree to work writing about movies and dancing with her plants.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In