5 Benefits of Self-adhered Products in Modular Construction

By Brian Chang, GCP Applied Technologies.

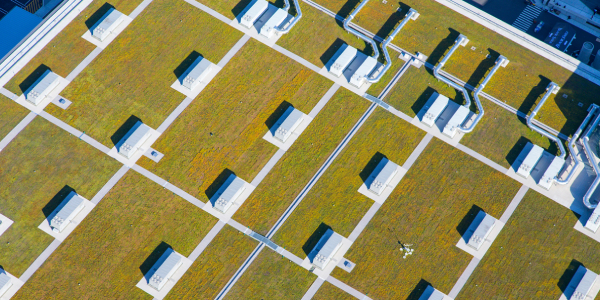

Modular construction creates less waste and reduces project timelines.

The process of modular construction is quicker than conventional building methods and easier on the environment. Due to these qualities, modular construction has grown rapidly in the previous years. Construction professionals also choose modular construction because it produces less waste, has a more airtight construction, is safer for crews — especially in an indoor construction environment — and reduces project timelines.

What if you could accelerate those benefits even further? Well, you can. With the right products, modular construction can be even more efficient.

A product category that is often overlooked when it comes to modular construction but fits seamlessly into the process is self-adhered building products. Their ease of application eliminates laborious and time-consuming fastening, taping and detailing procedures, among other benefits. Here are the top five reasons to use self-adhered building products in modular construction:

1 – Weight matters - As the building is constructed off-site and then transported to the building site, weight is a significant consideration in modular construction to keep costs down. A procedure called “light weighting” is often conducted to shrink every ounce of the truck's weight to improve the miles per gallon. Using self-adhered products eliminates the need for fasteners, making the modules lighter. The lower weight equals lower transportation costs and a lower overall cost for you as the building owner. These savings are typically much greater than the marginal additional cost of self-adhered products.

2 – Windproof - Self-adhered products stand up to winds during transport. They don’t blow around or get destroyed. For instance, GCP’s VYCOR® enV-S® fully adhered weather barrier seals to the substrate, solving this transportation challenge of the modular delivery process. Truck drivers have put VYCOR® enV-S® weather barrier to the test by driving at highway speeds and the weather barrier survived nicely in transit. Standard building wraps can pull away from the sheathing, like sails in the wind, and often end up on the roadway, requiring rework on the jobsite.

3 – One person application - Self-adhered products can often be applied by one person. Most house wraps are provided in 48-inch rolls, but GCP’s VYCOR® enV-S® weather barrier comes in 40-inch rolls, and GRACE ICE & WATER SHIELD® self-adhered roofing underlayment comes in 36-inch rolls. These shorter lengths combined with the self-adhesive application can help make it easier for one person to apply them at a modular station.

4 – Eliminate steps - Traditional house wraps are applied with nails or fasteners that could create leaks at every hole. In the field contractors are then supposed to tape over those seams. VYCOR® enV-S® weather barrier does not require mechanical fasteners to install, and thus does not require laborious taping of seams onsite. It also can be installed on most wood substrates without aid of any special primer materials, eliminating steps.

5 – Reduce tools and costs - Self-adhered building products do not require nail guns, tape, cap fasteners and other products for application. All that is needed is the product itself, extracting three to five tools from the process. Eliminating this expensive equipment not only makes the application easier, but it also reduces the budget and application time.

The features of self-adhered building products complement the modular construction process. They are independently and easily applied in the workshop, and eliminate steps and tools needed. Utilizing premium products that accelerate the benefits of modular construction is one way to do so, increasing the efficiency of the building process and quality of the completed structure.

Have a question? AskARoofer.

Find your local roofing contractor in the RoofersCoffeeShop® Contractor Directory.

Original article source: GCP Applied Technologies

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In