A Truly Resistant Roofing Underlayment – The Polystick XFR Solution

Learn more about Polyglass’ Polystick® line of self-adhesive (SA) underlayments for commercial and residential buildings.

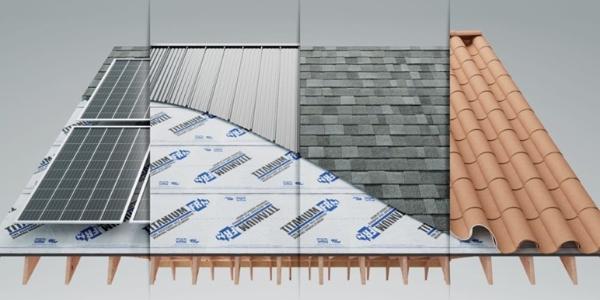

Roof underlayments are critical for the performance and longevity of any roof system. They separate roof coverings and substrates and act as a second weatherproofing barrier to prevent moisture from penetrating roof coverings. They also provide temporary weather protection until a roof covering is completely installed.

But not all underlayments are made equal, and commercial building owners, contractors and homeowners continue to struggle with their performance. Not surprising, as Building Codes such as IBC 2021 offer little guidance on underlayment performance for steep-sloped roofs. In fact, codes for most roof covering types require little more than a light-duty paper-based felt underlayment, which provides little protection to the building.

Roof worksites, in particular, are a continual orchestra of moving tradespeople and activities and are subject to repeated misuse and phasing of work. Most of these activities are unfavorable to underlayments, especially light-duty materials with inferior fastener sealability, such as synthetic-fabric-based products. While synthetic underlayments for steep-slope roof systems certainly promise a myriad of performance benefits, they fall short of delivery and just can’t hold up to self-adhesive membranes.

Polyglass solutions for a truly resistant underlayment

Polyglass’ Polystick® line of self-adhesive (SA) underlayments for commercial and residential buildings offers enhanced resistance against high temperatures and external fire, unmatched waterproofing and the strength to withstand harsh worksite conditions.

Polystick® XFR

Polyglass’ Polystick XFR is a dual purpose fire-resistant and self-adhered waterproofing underlayment. Polystick XFR was initially designed to provide maximum fire-resistance properties for various metal roof types, such as steel and copper roofing. With a textured film surface, Polystick XFR protects metal roof coverings from sticking and offers enhanced walkability.

Polystick XFR’s temperature resistance of up to 265°F makes it ideally suited for high-temperature roof covering systems. It is an excellent choice for nearly all roof coverings and is approved for application under roof panels, asphalt shingles and mechanically attached tiles.

Polystick XFR’s self adhered technology increases labor efficiency and roof dry-in speed. Polystick XFR features a slip-resistant film that protects the self adhesive compound and allows for safe and easy application.

Polystick XFR was the underlayment of choice for the Hyatt House Miami Hotel project in South Miami, which required 30,000 square feet of fire-resistant underlayment. Read more about the project here.

With an impermeable compound design and glass-fiber reinforcement, Polystick XFR offers all the things a quality performance underlayment should provide: strength, worksite resistance to trades, and enhanced external fire performance, without the need for sacrificial slip-sheets.

For more information about Polyglass products and techniques for all your low-sloped or steep-slope roofing needs, contact a Polyglass Contractor today!

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In